Board-to-Board Connector Selection Guide

Board-to-board (BTB) connectors are indispensable components in modern electronics, enabling seamless coupling of power and signal across stacked printed circuit boards. As the scale and complexity of electronic design escalate, these connectors have evolved beyond mere conduits. They now embody advancements in miniaturization, high-frequency transmission, and power density optimization. In high-performance embedded systems, the right BTB connector is not just a link—it is a critical enabler of system functionality, reliability, and design compactness.

Classifications and Characteristics of Board-to-Board Connectors

BTB connectors are not a one-size-fits-all solution. Selection depends on an interplay of factors: structural design, electrical and mechanical performance, application environment, and cost-efficiency. Below are the main categories with their defining features:

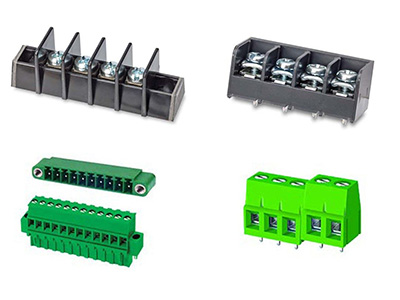

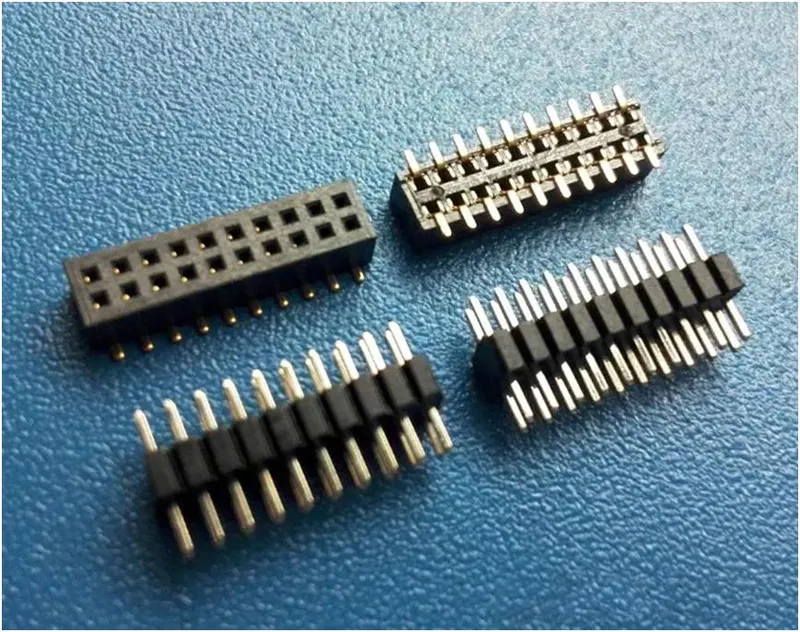

Pin Header and Socket (Male-Female Connectors)

Often dubbed as the “workhorses” of basic electronics, pin headers and sockets provide an inexpensive and robust connection.

Application Scenarios: Ideal for large-scale, low-end smart devices, development boards, and debugging interfaces.

Advantages: Economical, rugged, and easy to solder. Their firm mechanical interface offers superior current handling and convenient probing capabilities during testing.

Disadvantages: Bulky form factor, inflexible structure, and large pin pitch limit their utility in space-constrained or high-density designs. Scaling to hundreds of pins becomes impractical.

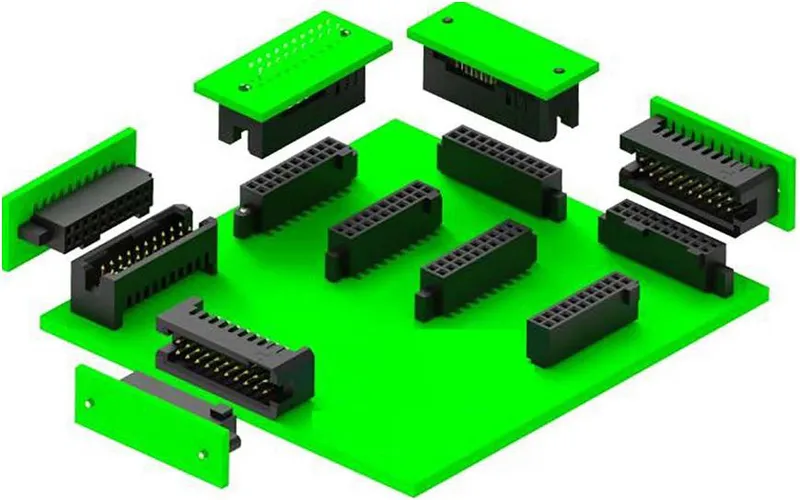

High-Density Board-to-Board Connectors

These are precision-engineered to fit tight layouts while offering extensive connectivity.

Application Scenarios: Ubiquitous in contemporary consumer electronics and compact smart hardware.

Advantages: High pin count within a limited footprint—up to 40 contacts per centimeter, doubling what traditional pin headers offer.

Disadvantages: Higher cost and limited durability against frequent mating cycles. Mechanical fastening during product design must be meticulously planned due to tight tolerances.

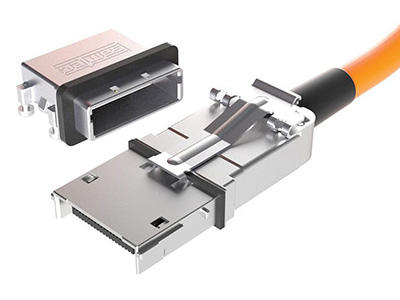

Reinforced Board-to-Board Connectors

A hybrid approach combining robustness with modularity. These connectors can interface with pin headers and support disassembly and reconfiguration.

Application Scenarios: Common in testing environments, development platforms, and stationary units like desktop PC chassis.

Advantages: Affordable and familiar to most engineers. Highly compatible with pin headers, simplifying temporary setups and diagnostics.

Disadvantages: Size and weight make them unsuitable for compact or mass-produced devices. Secure fixation is often challenging.

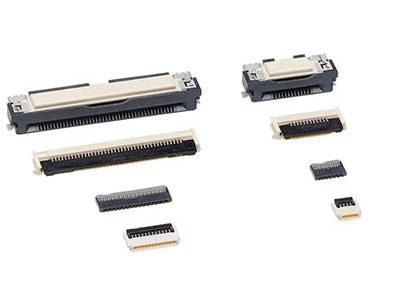

FPC Connectors / ZIF (Zero Insertion Force) Connectors

Flexible Printed Circuit (FPC) connectors are indispensable where flexibility, compactness, and versatility are paramount.

Application Scenarios: Ideal for linking motherboards to peripheral modules, secondary boards, or when routing signals through constrained or articulated pathways.

Advantages: Their slim profile and pliable nature make them invaluable in tight spaces. Economical and widely adopted in foldable or mobile designs.

Key Considerations for Selecting Board-to-Board Connectors

Structural and Dimensional Compatibility

Physical dimensions dictate initial feasibility. The connector must align with the PCB layout without causing spatial conflicts. Pin count and pitch (spacing between contacts) must correspond to the signal map of the application. For reflow-soldered surface-mount connectors, caution is required—excessive pin density can result in heat deformation, causing mid-section warping and subsequent cold joints or open circuits.

Electrical Performance

Electrical metrics are paramount in power and data-intensive applications.

Key Parameters: Maximum current rating, contact resistance, dielectric withstanding voltage, and insulation resistance.

Power Delivery: Ensure de-rated current capacity is sufficient, especially in power-intensive modules. Pins must withstand transient spikes and thermal buildup.

Signal Integrity: For high-speed interfaces like LVDS or USB 3.x, low contact resistance (typically within 10–100 mΩ) and controlled impedance are critical. Impedance mismatches can cause signal reflection, degrading data fidelity.

Mechanical Attributes

Durability and tactile characteristics influence long-term performance.

Insertion/Withdrawal Force: Important for user-accessible connectors. Excessive force increases mechanical wear; too little compromises connection integrity.

Mating Cycles: In frequently accessed interfaces (e.g., test points), the connector must endure repeated use without performance degradation.

Keying & Polarization: Essential to prevent reverse insertion, which can lead to catastrophic circuit damage.

Environmental Resilience

Connectors must operate reliably under expected environmental conditions.

Humidity & Corrosion Resistance: In moist or saline atmospheres, gold-plated or corrosion-resistant materials should be used to maintain conductivity and longevity.

Vibration & Shock Tolerance: In industrial automation or vehicular systems, connectors must be vibration-proof. Snap-fit designs or locking latches may be necessary to prevent accidental dislodging.

Conclusion

Choosing the right board-to-board connector is both an art and a science. It demands a holistic understanding of electrical constraints, mechanical design, environmental exposure, and future scalability. Whether for a high-density wearable device or a robust industrial module, precision in selection ensures reliable operation, manufacturability, and system integrity throughout the product’s lifecycle.

Shenzhen Gaorunxin Technology Co., Ltd