Common Mode Chokes vs. Magnetic Rings!

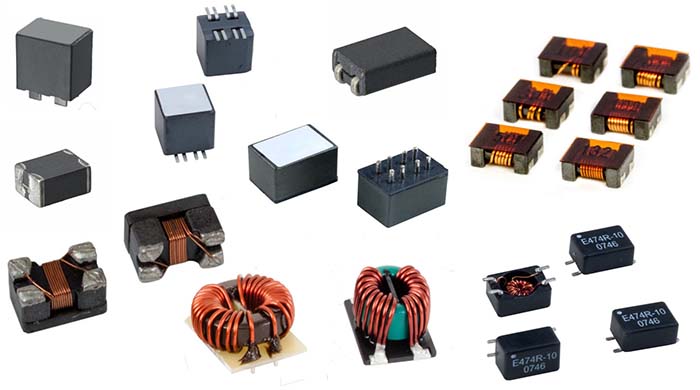

A common mode choke consists of two coils with identical turns and opposite winding directions on the same magnetic core. This symmetrical design creates distinct responses to common mode noise and differential mode signals. When common mode noise (interference with identical phase and amplitude in both conductors) flows through the coils, the magnetic fluxes generated by the two coils align in direction and superimpose in the core (as determined by the right-hand rule: grip the coil, align curled fingers with the current direction, and the thumb points to the magnetic field direction). This results in high inductive reactance (XL = 2πfL), blocking high-frequency common mode currents. Conversely, for differential mode signals (useful signals), the opposing currents create cancelling magnetic fluxes, reducing inductance to near zero and allowing unimpeded signal transmission.

Common mode chokes are reflective components, blocking noise by impedance mismatch. They reflect high-frequency noise back to the source rather than allowing propagation to the load.

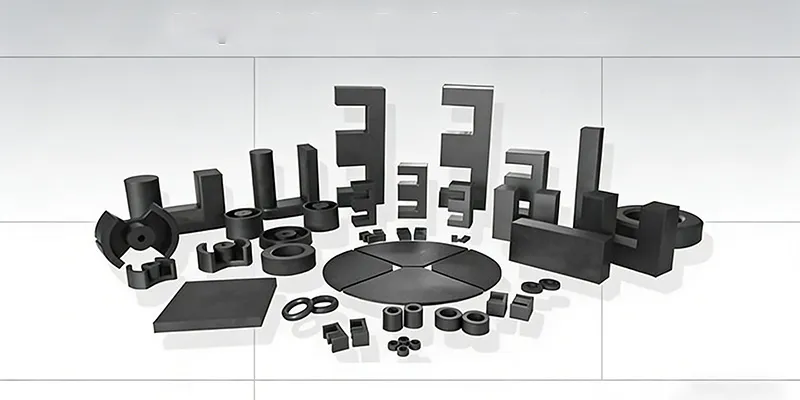

Magnetic cores with higher permeability provide greater common mode inductance for enhanced noise suppression but are prone to saturation under high currents due to lower saturation flux density. Low-permeability materials (e.g., silicon steel) resist saturation, making them ideal for high-current applications. High-permeability ferrites exhibit low losses in the MHz range, while low-permeability materials suffer from severe eddy current losses at high frequencies.

Magnetic rings (ferrite beads) are absorptive components, converting high-frequency noise energy into heat via electromagnetic losses rather than reflecting it. They rely on resistive impedance to dissipate noise.

When installed on cables, magnetic rings create a high-impedance path for common mode currents (due to additive magnetic flux) but minimal impedance for differential mode currents (single-turn flux).

Material Differences:

- Amorphous alloy rings have low hysteresis losses below MHz frequencies but degrade at higher frequencies due to declining permeability.

- Ferrite rings (nickel-zinc for 100 MHz–GHz, manganese-zinc for lower frequencies) suppress noise via hysteresis losses, with nickel-zinc excelling in high-frequency applications.

Shenzhen Gaorunxin Technology Co., Ltd