Revolutionizing Connectivity: Three Giants, Three Breakthroughs

The connector industry is witnessing a fresh surge of innovation as TE Connectivity, WAGO, and Jinling Electronics roll out new product lines tailored to the evolving demands of modern electronic infrastructure. These solutions are engineered to tackle the pressing challenges posed by miniaturized smart devices, compact electrical wiring systems, and the ever-tightening requirements of new energy and industrial automation.

Each company brings to market a distinctly focused product: TE’s 0.8mm ultra-slim IDC connector system, WAGO’s 221 Series 10-wire connector, and Jinling’s JL15EDGKDA-350 pluggable terminal block. Collectively, they redefine the standards for efficiency, adaptability, and reliability in the realm of electrical and electronic interconnects.

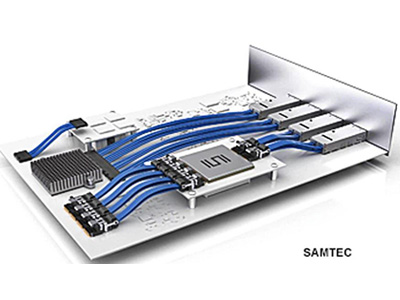

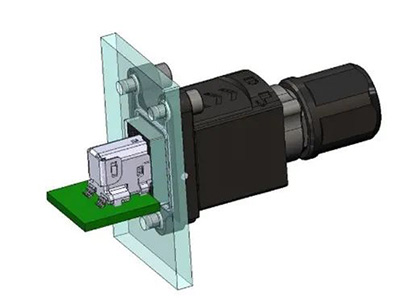

TE Connectivity: 0.8mm Ultra-Slim IDC Connector System

As smart electronics grow increasingly slender and densely packed, traditional connector formats become less viable. TE Connectivity addresses this trend with its newly unveiled 0.8mm ultra-slim IDC (Insulation Displacement Contact) connector system—designed with a keen focus on saving space, streamlining termination, and optimizing board real estate.

Key Features:

Slimline Architecture: With a centerline pitch of just 0.8mm, the connector dramatically reduces spatial footprint, ideal for compact consumer and industrial electronics.

Rapid Termination: Single-step IDC cable termination process accelerates assembly, improving production efficiency without compromising connection integrity.

Optimized PCB Utilization: Enables higher circuit density with reduced interference.

Cost & Delivery Efficiency: Competitively priced and engineered for rapid deployment to meet high-volume demands.

Application Spectrum:

IoT Devices: Home security systems, small appliances, smart meters, vending machines.

Data Communication Equipment: Servers, switches, modems.

Medical Electronics: Patient monitoring instruments.

Consumer Devices & Automation: Where sleek form factors meet rugged performance demands.

Technical Highlights:

Rated current: 1A

Constructed from high-temperature thermoplastics meeting UL94V-0 standards

Available in multiple gold plating finishes for enhanced durability

TE’s new connector system is a sophisticated response to modern demands for ultra-compact, high-efficiency interconnects that seamlessly blend form with function.

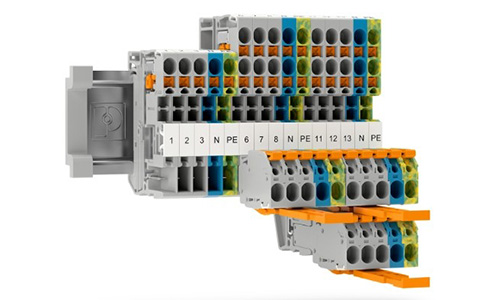

WAGO: 221 Series 10-Wire Connector

WAGO's 221 Series expands upon its acclaimed connector family by introducing a 10-wire variant, optimized for complex electrical installations. This new addition embodies precision engineering, combining compactness with broad compatibility and ease of use.

Product Advantages:

Fail-Safe Connections: Ensures robust connections across wires of the same potential, minimizing connection failures and reducing material waste.

Double-Layer Compact Design: Ideal for constrained environments such as distribution panels. The structured layout simplifies routing and facilitates maintenance.

Universal Wire Compatibility: Supports a broad range of wire types—0.14–4mm² fine-stranded and 0.2–4mm² solid core—accommodating diverse application scenarios.

Illustrative Model: 221-420

A standout within the series, this model delivers unparalleled convenience and reliability, embodying WAGO’s ethos of engineering precision.

Primary Use Cases:

Building Electrical Systems: Roller shutter control, heating distribution, ceiling systems, lighting, and safety control wiring.

Installation Flexibility: Supports both on-site improvisation and pre-planned wiring layouts, enhancing project adaptability and timeline efficiency.

WAGO continues to elevate expectations in the field of professional electrical wiring, offering tools that enhance productivity, ensure compliance, and reduce physical and operational clutter.

Jinling Electronics: JL15EDGKDA-350 Pluggable Terminal Block

Targeting mission-critical sectors like new energy, power distribution, and industrial control, Jinling Electronics introduces the JL15EDGKDA-350—an advanced pluggable terminal block built to deliver uncompromised reliability, user-centric design, and high mechanical resilience.

Standout Attributes:

Push-In Technology: Utilizes a spring-loaded contact system that allows for tool-free wire insertion. Compatible with cold-pressed, solid-core, and multi-stranded wires.

Dual-Row Configuration: One-input, two-output design enables space-efficient wiring and expands terminal density without enlarging footprint.

Stability & Flexibility: Supports both aerial and PCB-mounted configurations. Its mechanical design enhances resistance to vibration and thermal expansion.

Safety Assurance: Flame-retardant material compliant with UL94V-0 ensures secure operation across varied environments.

Performance Specifications:

Rated Current: 10A (AC/DC)

Rated Voltage: 300V

Dielectric Strength: 1600V (AC/DC)

Operational Temperature: -40℃ to +105℃

JL15EDGKDA-350 exemplifies how modularity, robustness, and compactness can harmonize to meet the intricate demands of today's electrified and automated infrastructures.

Conclusion: A Convergence of Innovation and Purpose

The simultaneous launches from TE Connectivity, WAGO, and Jinling Electronics signify more than product evolution—they mark a recalibration of what’s possible in modern connectivity. Whether addressing the constraints of ultra-slim IoT designs, enhancing the modularity of building installations, or fortifying the backbone of industrial power systems, these new solutions demonstrate a common drive: to deliver performance, precision, and peace of mind in a rapidly accelerating technological age.