High-Quality Sensors and Connectors: The Cornerstones of Logistics Robotics

In modern logistics systems, automation is no longer just a trend—it's the driving force. From in-warehouse product handling to last-mile delivery systems, robotic devices are fundamentally transforming the supply chain. Behind this revolutionary shift, high-performance sensors and connectors operate as the neural network and bloodstream, ensuring efficient and reliable operation of robotic systems.

Automation is Reshaping Logistics Transport

Traditional warehouse operations are rapidly evolving. With the rise of robotic automation systems, tasks like handling, picking, and loading have become intelligent and increasingly unmanned. Autonomous Mobile Robots (AMRs), with their adaptive navigation and cooperative abilities, have emerged as a central force in smart logistics. These systems encompass forklifts, tuggers, pallet trucks, and heavy-load carriers, meeting a wide array of transport demands.

The growth of e-commerce, rising labor costs, and the need for supply chain visibility have all fueled the demand for automation. AI and machine learning further empower robotic systems—not only to “move,” but to “understand” and “decide.”

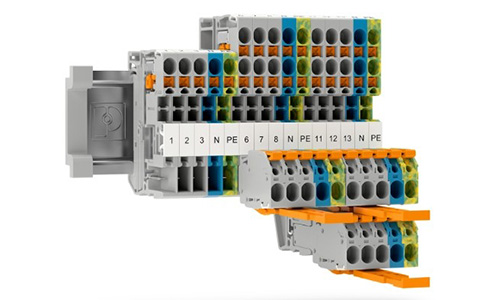

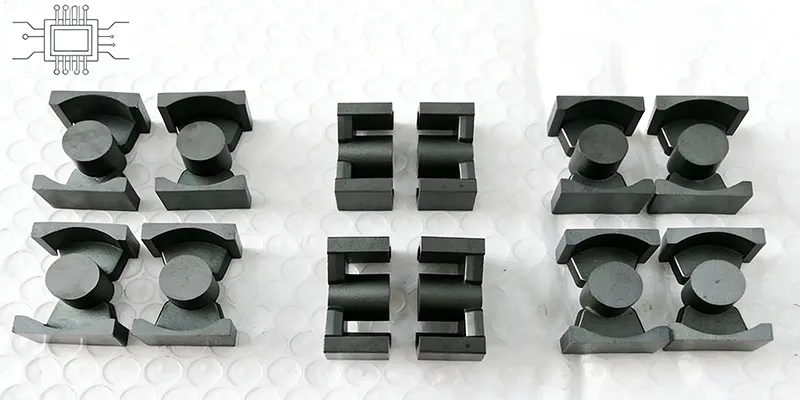

RF Connectors: The Communication Backbone of Autonomous Robotics

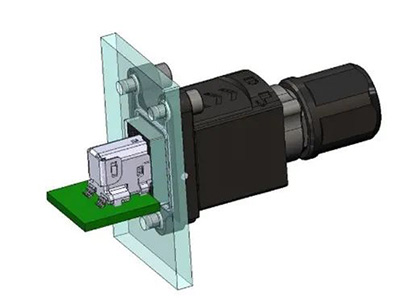

Communication is the lifeblood of industrial automation, and RF connectors play a critical role. Amphenol’s RFBNC RF connectors and cable assemblies provide the backbone for edge-intelligent AMRs. High-integrity RF transmission enables essential functions such as environmental sensing, visual processing, and motion planning.

In complex logistics environments, connectors must meet rigorous standards. They must be durable, interference-resistant, easy to assemble, and capable of maintaining performance in tight spaces, high humidity, and high-vibration areas. These demands make robust, industrial-grade RF connectors indispensable.

Diverse Forms of AMRs

Autonomous Mobile Robots now exist in a variety of specialized forms, each tailored to specific logistics functions:

Forklift: Handles vertical transport and high-shelf operations

Assembly Line Robot: Executes point-to-point transport in production systems

Pickers: Uses vision systems to identify and pick items

Load Transfer Units: Automate product movement between locations

Light Load Transporters: Operate in tight indoor environments

Tuggers: Pull chains of carts efficiently

Pallet Trucks: Manage pallet stacking and transfer

Heavy Load Transporters: Move large goods and industrial equipment

These machines work together to improve operational efficiency, accuracy, and reduce dependency on manual labor.

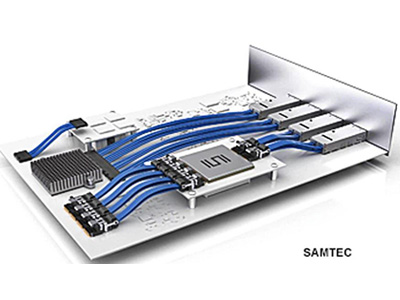

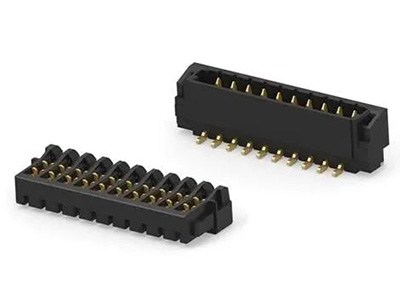

RFF Connectors and the Future of Logistics Transport

Robotic systems are extending their capabilities from inside warehouses to the final leg of delivery. Amphenol’s RFF connectors provide secure communications in mobile logistics—from warehouse-to-warehouse transport to last-mile autonomous delivery fleets.

Semi-autonomous trucks and mid-sized robotic vehicles are already supporting human drivers. Fully autonomous fleets, operated by “virtual drivers,” are forecasted to launch within the next two years, as announced at the 2025 Manifest Supply Chain & Logistics Conference. Even in the event of critical system failures, these vehicles are engineered for safe operation, thanks to robust hardware design and high-reliability connectors.

Sensors: The Sensory Core of Robotic Systems

Sensors are the eyes and ears of any robotic system. In logistics robotics, they play an indispensable role in environmental perception, data acquisition, and decision feedback. These miniature devices measure temperature, pressure, light, motion, and more, allowing robots to respond intelligently to their environment.

Key sensor types used in autonomous vehicles include:

LiDAR: Provides high-resolution 3D spatial mapping

Radar: Detects object distance and velocity, crucial for collision avoidance

Cameras: Capture real-time visual data, processed by AI for navigation and object recognition

Position and Proximity Sensors: Assist with navigation, obstacle detection, and spatial awareness

Heilind offers a wide selection of TE sensors engineered for harsh conditions, maintaining high sensitivity and signal stability in dynamic environments.

Future Trends in Sensor Technology

As fully autonomous vehicles approach mainstream deployment, sensors must become more compact, more precise, and more robust. Engineers are pushing the boundaries of sensitivity, interference resistance, and multimodal integration.

Reliability and service life remain critical metrics, especially when combining components from different manufacturers. System designers must ensure full interoperability and flawless synchronization to guarantee optimal performance across mission-critical applications.

Conclusion

From nimble AMRs navigating warehouse aisles to autonomous trucks cruising highways, the logistics industry’s transformation hinges on components you rarely see: high-quality sensors and connectors. They operate in silence, but they enable the intelligent orchestration of modern logistics. As technology continues to evolve, these "sensory nerves" and "communication arteries" will remain at the heart of next-generation robotic systems.

Shenzhen Gaorunxin Technology Co., Ltd