Material Science and Reliability Research of USB Type-C Connectors

Abstract

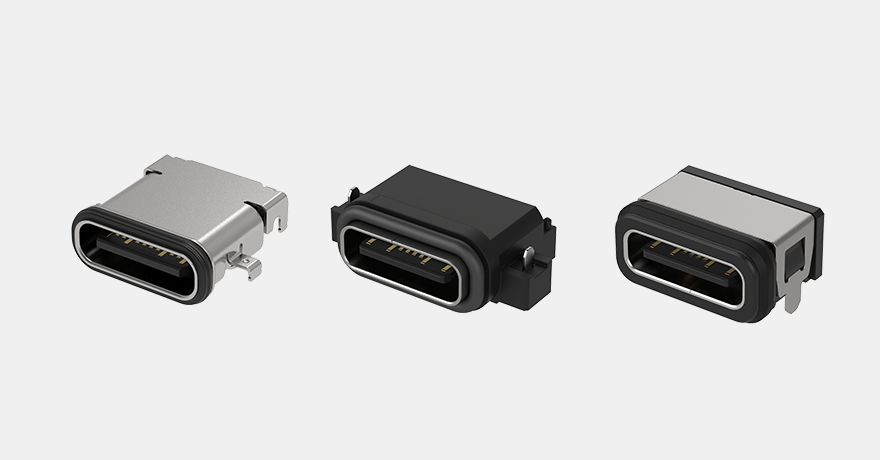

With the widespread adoption of USB Type-C connectors in modern electronic devices, the demand for high-power transmission, corrosion resistance, and mechanical stability has significantly increased. This paper comprehensively analyzes key issues in the design and material selection of USB Type-C connectors, exploring the impact of electrical insulation, mechanical properties, and corrosion resistance on connector reliability. Through experimental research and theoretical analysis, this study evaluates the performance of different materials in USB Type-C connectors and proposes optimization strategies to meet growing market demands.

1. Introduction

USB Type-C connectors have become a standard in modern electronics due to their high-speed data transfer and power delivery capabilities. However, increasing power demands and complex usage environments present challenges, including electrical insulation, mechanical stability, and corrosion resistance. This paper examines these challenges and proposes solutions to enhance connector reliability and safety.

2. Structure and Material Requirements of USB Type-C Connectors

2.1 Structural Design

USB Type-C connectors must support high-power transmission (up to 240W, 48V) and high-speed data transfer. Their design features a tongue-like structure with symmetrically arranged metal pins encased in plastic. With pin spacing as narrow as 0.5mm and plastic walls as thin as 0.1mm, material selection is critical for mechanical stability and electrical insulation.

2.2 Material Requirements

Key material requirements include:

- High CTI Rating: Ensures resistance to electrical leakage and arcing.

- Superior Mechanical Properties: Thin-walled materials must maintain strength, stiffness, and processability.

- Corrosion Resistance: Stability in high humidity, high temperature, and chemically corrosive environments.

3. Electrical Insulation Performance of Connector Materials

3.1 CTI Rating

Comparative testing shows PA46 withstands 60 electrolyte droplets without failure, while LCP fails after 12 droplets. Over 70% of major smartphone brands use PA46 for USB Type-C connectors due to its reliability.

3.2 Reliability in High-Temperature, High-Humidity Environments

Testing reveals that failure modes in harsh conditions depend not only on material properties but also on interlayer adhesion, weld line strength, and plugging durability.

- Interlayer Adhesion: PA46 exhibits superior bonding strength vs. PPA and LCP, preventing electrical faults.

- Weld Line Strength: PA46 outperforms PPA (22–40 MPa) and LCP (15–17 MPa) with 50–60 MPa strength, reducing cracking risks.

- Corrosion Mechanisms: Additive-induced electrochemical reactions in humid environments necessitate material formula optimization.

4. Material Optimization Strategies

4.1 Enhancing Interlayer Adhesion

PA46’s high amide group density (–CONH–) enables strong hydrogen bonding, delivering seamless interlayer fusion vs. PPA/LCP’s visible cracks.

4.2 Increasing Crystallinity

Annealing (140–260°C) improves polyamide crystallinity, boosting corrosion resistance.

4.3 Additive Optimization

Selecting non-reactive additives minimizes electrochemical corrosion.

5. Experimental Results

Optimized PA46 (Stanyl®) demonstrates:

- CTI integrity after 60 electrolyte droplets.

- Exceptional corrosion resistance in 85°C/85% RH conditions.

- High interlayer adhesion (50–60 MPa) and weld line strength.

6. Future Outlook

Research directions include:

- New Materials: Higher adhesion, weld strength, and toughness.

- Process Optimization: Reducing defects in injection molding.

- Environmental Adaptability: Extreme-condition performance studies.

These advancements will ensure USB Type-C connectors meet evolving demands, driving next-gen electronics.

Shenzhen Gaorunxin Technology Co., Ltd