- Home

- Industry News

- TDK Launches Industr...

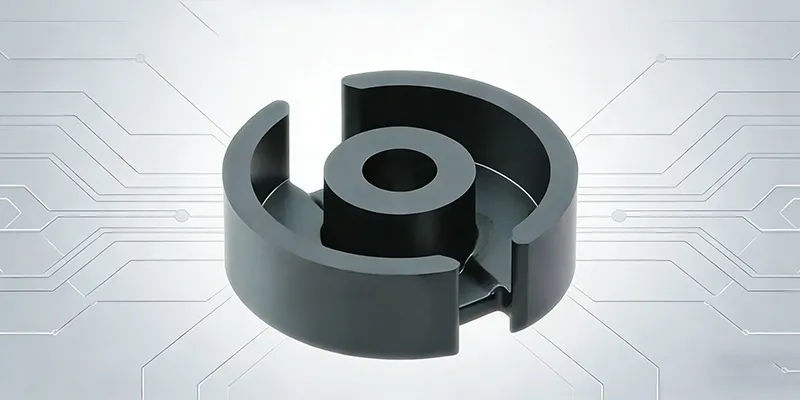

Introduction: Advancing Noise Suppression for High-Current Circuits

TDK Corporation has announced a groundbreaking expansion to its MPZ1608-PH series of multilayer chip beads, designed for power lines in both automotive and commercial applications. With mass production commencing in May 2025, this new addition sets a benchmark in miniaturized, high-current electromagnetic compatibility (EMC) components. The bead, housed in a compact 1608 package (1.6 × 0.8 × 0.6 mm), boasts an impressive 8A current rating—currently the highest in the industry for this form factor.

Unprecedented Current Rating in a Compact Form Factor

The newly released MPZ1608-PH series achieves an industry-first: an 8-amp current rating in a 1608-sized chip bead. This innovation addresses a long-standing limitation in high-current circuit design. Traditionally, circuits handling 8A or more required two or more chip beads to be connected in parallel. However, this workaround often leads to non-uniform current distribution between components—an inefficiency that can degrade circuit performance and reliability.

TDK’s new solution eliminates this bottleneck. By consolidating the function of multiple components into a single high-efficiency chip bead, engineers can reduce complexity, improve space utilization, and ensure more stable current flow through power lines.

Reduced Footprint and Optimized Circuit Design

Space is a precious commodity in modern electronic design. By replacing two conventional 1608 chip beads with a single MPZ1608-PH component, the occupied PCB area can be reduced by up to 50%. This remarkable footprint reduction enables more compact and streamlined circuit layouts—particularly advantageous in densely packed automotive control units, power modules, and industrial power converters.

Simplifying circuit architecture not only saves space but also enhances design reliability. Fewer components mean fewer potential failure points, contributing to better thermal balance and more efficient heat dissipation.

High-Temperature Endurance for Demanding Applications

The MPZ1608-PH series is engineered to operate in environments where thermal stress is the norm, not the exception. With a rated operating temperature of up to +125°C, these chip beads are optimized for the harsh thermal conditions found in under-the-hood automotive electronics, industrial machinery, and other high-reliability systems.

TDK's advanced materials and proprietary structural design deliver exceptional thermal resistance without compromising electrical performance. This makes the MPZ1608-PH an ideal fit for applications where both high current capacity and elevated operating temperatures are required.

Tailored for Emerging Market Demands

Built upon TDK’s proprietary materials and multilayer design techniques, the MPZ1608-PH series exemplifies how component innovation can align with evolving industry needs. As the demand for compact, high-current, and noise-suppressing components grows across sectors—ranging from electric vehicles to industrial automation and next-gen consumer devices—TDK is positioning itself at the forefront of EMC component evolution.

The MPZ1608-PH not only strengthens power line noise suppression but also enhances the overall integrity of power delivery systems. These components play a pivotal role in elevating the quality of the power circuit, acting as a reliable buffer against unwanted high-frequency interference.

Conclusion: A Milestone in Power Line Component Technology

TDK’s latest high-current chip bead offering represents more than a size or current rating breakthrough—it signifies a strategic step toward more efficient, resilient, and space-conscious electronic design. With its 8A rated capability, thermal resilience, and space-saving profile, the MPZ1608-PH series is set to become a cornerstone in next-generation automotive and industrial systems.

By expanding the boundaries of what's achievable in miniaturized EMC components, TDK is not only addressing the pressing needs of power integrity—but also paving the way for more robust and reliable electronics in every application domain.

Shenzhen Gaorunxin Technology Co., Ltd