Why Do MnZn Power Ferrite Cores Have Curie Temperatures Above 200°C, While High Permeability Cores Only Reach Around 100°C?

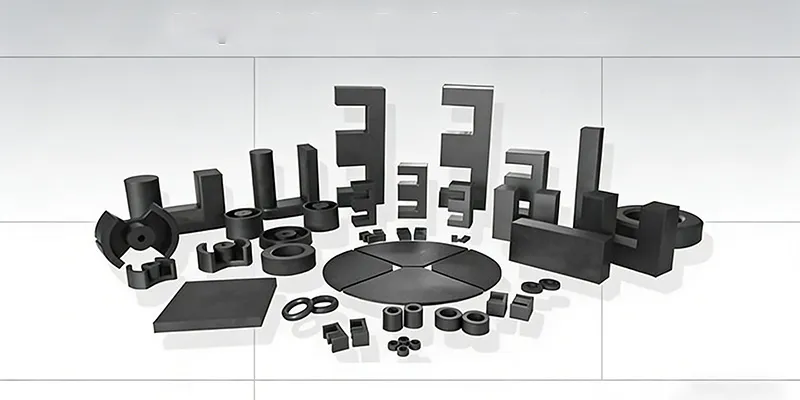

MnZn ferrite materials are extensively utilized in electronic transformers, filters, and power conversion systems due to their outstanding magnetic properties. However, a notable divergence exists between MnZn power cores and high permeability cores: the disparity in Curie temperature (Tc). While power ferrite cores routinely exceed 200°C, high permeability variants often fall within the 100°C to 150°C range. This divergence stems from differences in composition, microstructure, and design priorities.

MnZn Power Materials: The Fortress of High Frequency Performance

As electronic devices trend toward lightweight, compact, and high-efficiency designs, the operating frequency of switching power supplies continues to rise. This development imposes increasingly stringent requirements on magnetic core materials. MnZn power ferrites have emerged to meet these demands, offering high saturation magnetic flux density (Bs), elevated Curie temperature (Tc), and low core loss (Pe)—critical traits for reliable performance in high-frequency, high-power environments.

Through refined crystal structuring and optimized composition, these materials maintain stable magnetic properties even under extreme operating conditions. The elevated Bs supports high magnetic flux densities, while the high Tc ensures thermal robustness, preserving magnetic domain order despite intense heat.

MnZn High Permeability Materials: Designed for Sensitivity in Signal Applications

In contrast, high permeability MnZn ferrites are tailored for sensitivity to low magnetic flux variations. Their most vital attribute is initial permeability (μi), making them ideal for signal processing, filtering, and telecommunications.

These materials reduce the number of coil turns required for a specified inductance, thus minimizing DC resistance and its related power loss. This results in higher efficiency and smaller component size—critical for modern communication systems. However, achieving such high μi values involves material trade-offs that compromise thermal stability and lower the Curie temperature.

Origins of the Tc Disparity: A Closer Look

1. Compositional Differences: A Subtle Balancing Act

While both core types are based on the MnO-ZnO-Fe₂O₃ system, their specific ratios and additive elements vary significantly.

Power cores contain higher Fe₂O₃ content and are balanced with MnO and ZnO to form a stable crystal lattice. This lattice structure restricts the movement of magnetic domains, allowing them to remain ordered even at high temperatures, thus elevating the Curie point.

High permeability cores often boost MnO content to maximize magnetic sensitivity. While this enhances permeability, it weakens lattice stability under thermal stress, reducing the Curie temperature.

Power cores also frequently incorporate trace elements like cobalt (Co) or nickel (Ni), which reinforce lattice cohesion and further elevate Tc. In contrast, high permeability cores typically use minimal or no such additives to avoid compromising permeability, thereby accepting a lower Tc.

2. Microstructural Discrepancies: Where Grain Size Tells the Story

The performance of a magnetic material is deeply rooted in its microstructure.

Power ferrites undergo a precise sintering process that yields large, well-defined grains. This structure creates stronger barriers to domain wall motion, requiring higher thermal energy to disrupt magnetic order—resulting in a higher Curie temperature.

High permeability cores, however, favor smaller grain sizes and more intricate grain boundaries to increase μi. This leads to more domain walls and easier mobility, meaning thermal agitation at lower temperatures can disorder the domains more readily, thereby reducing Tc.

The “tightness” or “looseness” of the internal grain architecture determines the material's thermal resilience—a meticulous dance in structural engineering.

3. Performance Requirements and Design Intent: Function Drives Form

Power cores are engineered for energy conversion tasks involving high currents, high magnetic flux, and elevated ambient temperatures. As such, materials are specifically designed for high thermal endurance, and Curie temperature is a top design priority.

High permeability cores serve in low-power, low-temperature applications such as filtering and signal transformation. These use cases demand magnetic sensitivity over thermal robustness. Thus, design priorities shift toward maximizing μi, even if it means sacrificing Tc.

In both cases, the material is optimized not for general superiority, but for excellence in its specific application domain.

Conclusion: Precision in the Art of Material Design

The world of MnZn ferrites is one of balance, trade-offs, and precision. Behind every performance metric lies a deliberate engineering decision. High or low Curie temperature is not a value judgment but a response to differing technical requirements.

Much like a scalpel and a sledgehammer—both tools of craftsmanship but suited to vastly different tasks—MnZn power cores and high permeability cores each shine in their own domain. In the kingdom of magnetic materials, each plays a distinct and indispensable role.

Shenzhen Gaorunxin Technology Co., Ltd